MatLor, LLC patented pre-sprayed polyurea liners for seamless containment applications. Our 100% pure polyurea liners are durable, waterproof, and chemical and fire resistant are used for 100 of different markets and applications.

Polyurea Containment Liner Applications

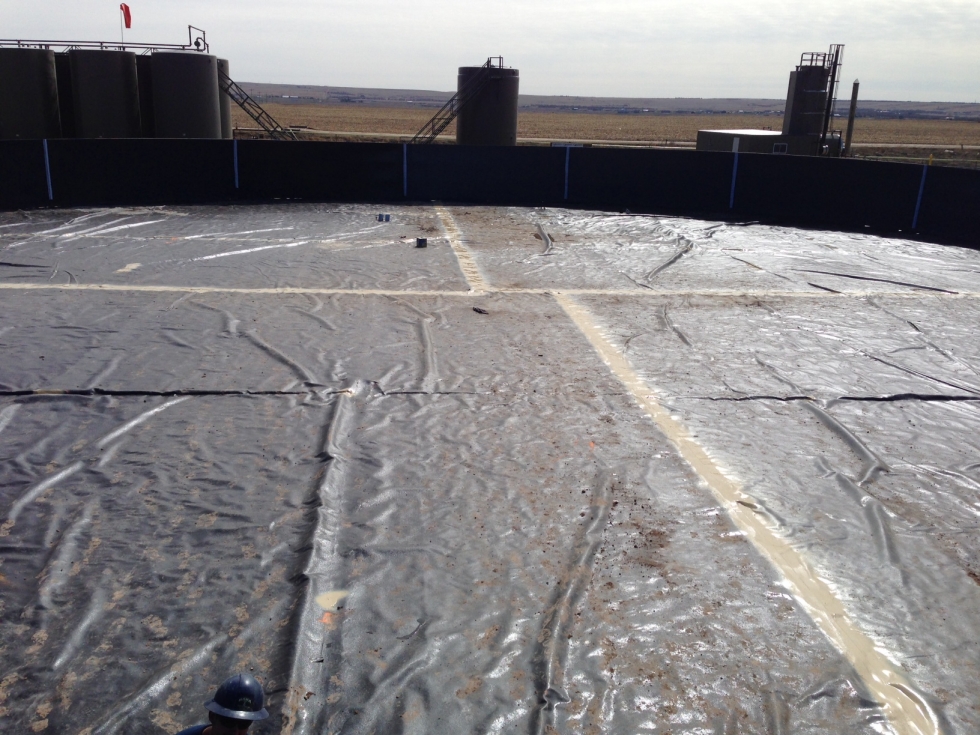

Secondary containment, waterproofing, tanks, pipelines, roofing, vapor barriers, fire retardant, frac ponds, fuel containment…

ROBOLINER®

RoboLiner® is patented (US 8,500,941 B2 & US 9,056,714 B2) pre-manufactured composite liner system comprised of spun-woven geotextile and a 100% solids pure polyurea system. RoboLiner® may be used by itself or in combination with other materials to produce wearing courses and resilient surfaces on a variety of substrates. RoboLiner® is inert, it will not hydrolyze, leach, or contaminate other materials,and is bond-able and paint-able. RoboLiner® is relatively moisture and temperature insensitive, allowing application in the most problematic ambient conditions.

RoboLiner® is a patented superior composite liner designed specifically for industrial applications receiving intermittent attack from contained materials. RoboLiner® is flexible, accommodating to movement of the substrate, yet strong enough to remain intact under all conditions except major structural dislocations. With or without reinforcements, RoboLiner® may be used in transitional areas in interior or exterior applications.

Ideal for Applications in:

- Secondary containment

- Industrial facilities

- Unsalvageable concrete substrates

- Below grade waterproofing

- Above grade waterproofing

- Water & wastewater treatment

- Lift station manholes

- Wet wells

- Penetrations & terminations

Advantages:

- 100% solids, no VOC’s

- Ease of installation

- Tough, seamless elastomeric membrane

- Pre-manufactured robotically in a controlled environment

- Excellent thermal stability

- Minimal downtime

- Arrives to project fully cured and ready for installation

- Remains flexible in colder temperatures

- Good UV stability

- Reduced material waste

- Low permanence rate

- Good resistance to a wide range of chemical attack

- Installation temperature range from -40°F to 350°F

- No heat welded seams necessary